From design and engineering through to fabrication, maintenance and approval

What we can

Production and maintenance of equipment needed, you can rely on MCL Apparatenbouw!

MCL Apparatenbouw is a company that manufactures process equipment for the (petro-)chemical

industry, the pharmaceutical industry and the energy sector. We engineer, manufacture and install

our equipment to the wishes of our clients. Our aim is to do fast repair and maintenance when there

is a malfunction so the production process of our clients will be fully utilised.

MCL Apparatenbouw was founded in 1978 and exists of 45 experienced employees (and we also

work with approximately 25 external employees). Craftsmanship and current professional knowledge

are just as important to us as timelines and reliability. Thanks to our hands on culture and can do

mentality, MCL is also the best partner for quick replacements and repair during breakdowns. We are

solution-oriented and think along with you. Together we find a suitable answer to your question.

MCL Apparatenbouw provides a turn-key solution to fully facilitate you during your process.

Our technical competences:

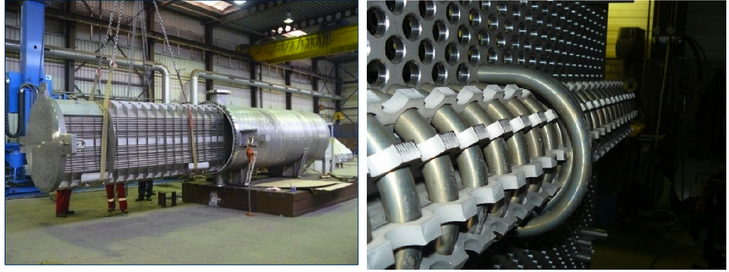

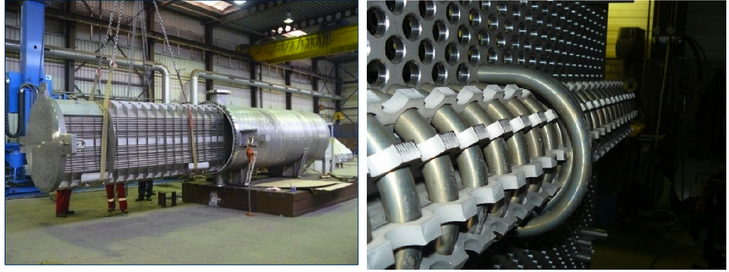

Type of equipment:

- Heat exchangers, type shell & tube and airfin

- (Pressure)vessels

- Columns

- Reactors

- (Storage)tanks

- Lamont vessels

- Complex piping systems

- Filters

- Skids, with mounted equipment

Pictures next to /below list “Type of equipment”:

Dimensions of equipment and workshop:

- Maximum dimensions equipment 6000 x 40000 x 100 (Ø x l x t), 100 Ton

- Separate carbon steel hall and stainless steel hall

- Dimension factory 3600 square meter

- Lifting capacity: 2 x 20 Ton-cranes

- Lifting height: maximum of 8,5 meter by height adjustable pit

Pictures next to /below list “Dimensionsof equipment and workshop”:

Diversity in processed materials:

- Carbon steel, various gradations

- Stainless steel, various gradations

- Duplex, Superduplex and molybdenum-free Duplex steel

- High-alloy steel such as Monel, Inconel, Cunifer, Hastelloy

- Titanium, various gradations

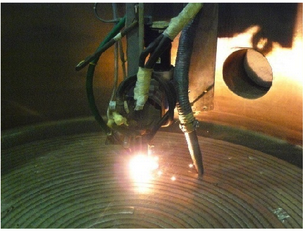

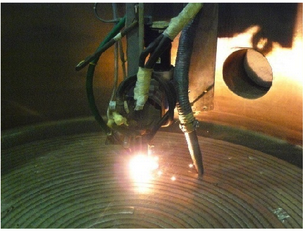

Welding techniques:

- Welding processes: GTAW (141), GTAW-ORB (141-ORB), SMAW (111), GMAW (135), FCAW

(136), GMAW-STT (135-STT), SAW (121), SAW-band welding (122), ESW-band welding (721)

- Welder qualifications: ASME IX, EN 9606-4, EN9606-1 en EN14732

- Welding method qualifications: EN 15614-1, EN 15614-7, EN 15614-8, ASME IX, AWS D1.1

Pictures next to /below list “Welding techniques”:

Processing competences:

- Lathing conventional (caroussel) and CNC

- Cuttering conventional

- CNC milling

- Conventional and CNC drilling

- Plasma cutting (3D)

- Conventional and CNC rolling

- Bending

- Assembling

- Cutting

- Sawing

Pictures next to /below list “Competentences in processing”:

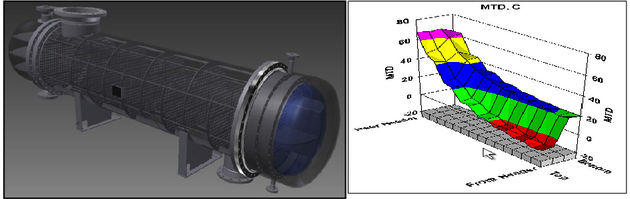

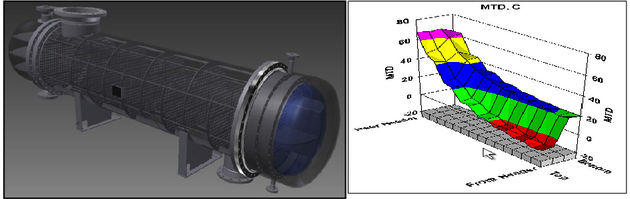

Engineering competences:

- Advanced 3D engineering

- Engineering software such as:

o Inventor 2019 (3D)

o Autocad 2019

o VES 2018

o FEA (Failure Mode Effect) analyses

- According to the (Inter)national authorities and customer specifications

- Various mechanical calculations according to certification and authorization codes:

o RToD (Regels voor Toestellen onder Druk)

o ASME VIII div 1&2

o AD-M, TEMA

o PD5500

o EN 13445

Pictures next to /below list “Engineering competences”:

Certificates:

- ISO 9001/2015

- ISO 14001: 2004

- OHSAS 18001: 2007

- VCA P 2008/5.1 (for Petrochemistry)

- WHG (TÜV)

- PED 97/23/EC category IV module H/H1

- ISO 3834-2

- AD2000 / merkblatt HP0

Pictures next to /below list “Certificates”:

Dimensions of equipment and workshop:

Dimensions of equipment and workshop:

Diversity in processed materials:

Diversity in processed materials:

Processing competences:

Processing competences:

Engineering competences:

Engineering competences:

Certificates:

Certificates: