Applications

Heat exchangers

Type of Heat Exchanger Rod baffle

- PED Cat. IV / module G

- Design Code: RtoD

- Diameter / length: OD Ø 1200 mm, length 28.000mm

- Total of rodbaffles per heat exchanger: 162 pieces

- Total of condensor pipes: 1362 pieces

- Measurements condensor pipes : Ø 19,05 x 1,65 mm. length 24.998,00 mm (total length of

66 kilometer) - Material shellside ASTM A516 Gr. 70

- Material tubeside: Duplex , 1.4462

Columns

- OD. Ø1800mm./Ø2200mm.; Length 31.402,00 mm.

- Empty weight : 40.320 kilogram

Pressure vessels

- Double wall coil

Skid with mounted equipment

- Weight construction including equipment and pipes: 130 tons, transportation weight 5

modules; 20-30 Ton each - Equipment: 1 filter; 8 shell & tube heat exchangers, 2 airfinned coolers, 18 pressure vessels,

columns and absorbers; 4 reactors - Material for pipes equipment; P265GH, 304L, 316L, P9, P11, 2 1/4 –Cr.-mat, 9 –Cr.-mat

- Lead time approximately 15 months, man-hours prefabrication-assembling (65,000 hours)

modules at MCL Apparatenbouw location

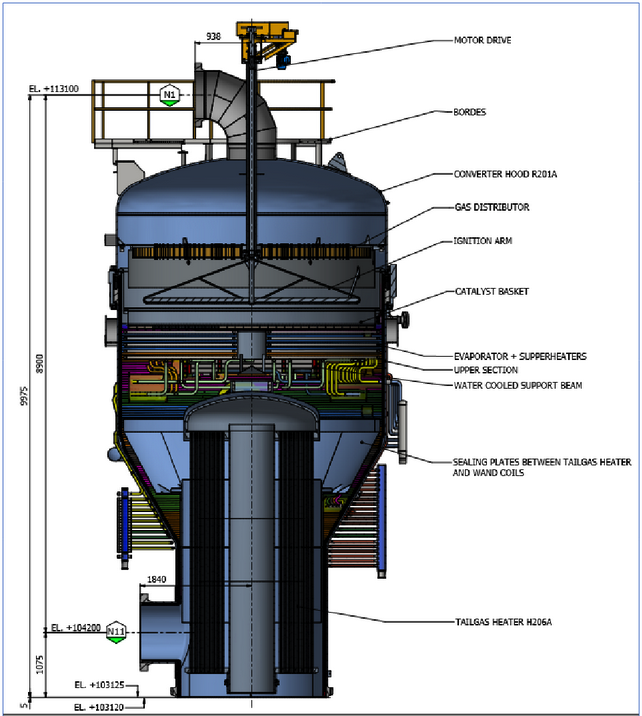

Lamont vessel

Weight: 58 Ton

- Uppersection including: Catalyst basket, water-cooled support beam, wall spiral, evaporator,

Superheater, clamps, weight; 40 Ton - Converter Hood including gas distribution plate, swing arm, geared motor and platforms,

weight; 18 Ton

Main dimensions: diameter 4.500 mm, height 11.500 mm, thickness 20 mm

Materials:

- Uppersection: 1.4311, 1.4306, 1.4541, 1.4876, 1.4841, 1.4986, 2.4851

- Converterhood: 1.4311, 1.4306, 1.4550

- Catalystbasket: Alloy 600

- Wall spiral: P235GH-TC2

- Water-cooled support beam: 16Mo3

- Evaporator: P235GH-TC2

- Superheater: 1.4910

- Headers and pipes: P235GHTC2, 16Mo3, 10CrMo910

- Heat shild: Alloy 800H